Quality

At Mid-Continent Machining, Inc., quality assurance begins on the shop floor with our operators performing meticulous in-process inspections for every part produced. Each component is carefully measured during production to ensure it adheres to strict specifications, reducing the risk of defects and enhancing consistency.

We employ Statistical Process Control (SPC) methods to monitor and document the manufacturing process, guaranteeing that every part meets or exceeds customer requirements. We can also employ Production Part Approval Process (PPAP) protocols when requested.

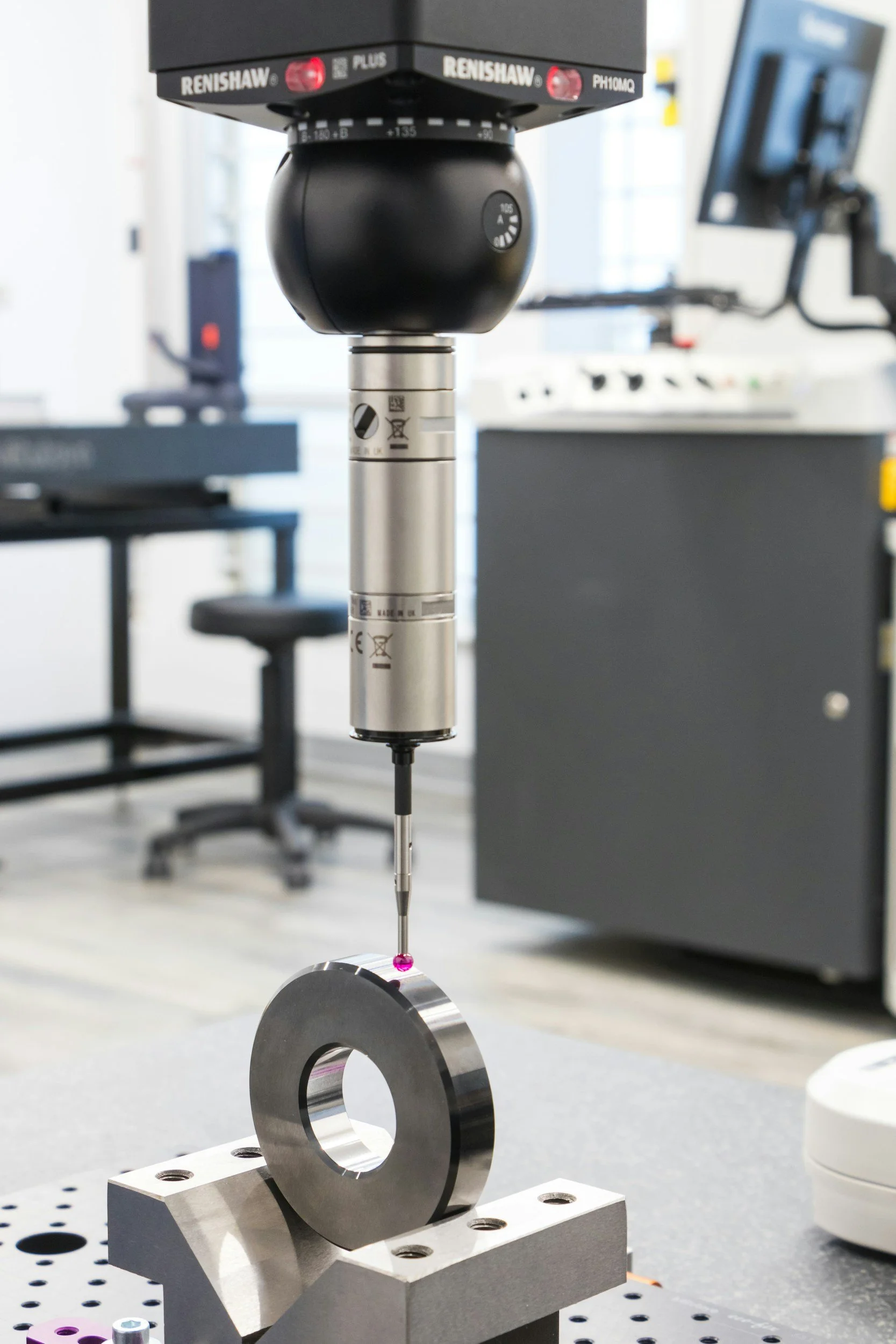

Our temperature-controlled inspection laboratory is equipped with advanced precision instruments, including Mitutoyo and Brown & Sharpe equipment, Coordinate Measuring Machines (CMM), hardness testers, and surface testers.

Our comprehensive suite of QA verification tools includes a full range of calipers, micrometers, height gauges, surface blocks, pins, and thread inspection micrometers and rings.

This robust inspection capability ensures that every part leaving our facility meets the highest standards of accuracy and reliability.

Our quality management system is compliant with ISO9001:2015.

We conduct two QMS management reviews yearly, along with an internal audit of all systems.

Our inspection equipment is calibrated yearly and traceable to NIST.